Welome To Vist Tongyun Bronze Sculpture Foundry

A question we often hear is “How are bronze statues created?” The bronze sculpture process is called

Lost Wax casting, and is an ancient method that dates back centuries. Today, artwork is cast at fine art

casting foundries. We own and operate our own facility called Tongyun Bronze Foundry in Tang County,

Baoding City,Hebei Province and provide fine art casting services for many other artists from all over the

world. While our primary casting service is fine art sculpture in bronze, we also cast our work in others

metals. To learn more about our foundry visit www.tongyundiaosu.com or call 0086-15188960033.

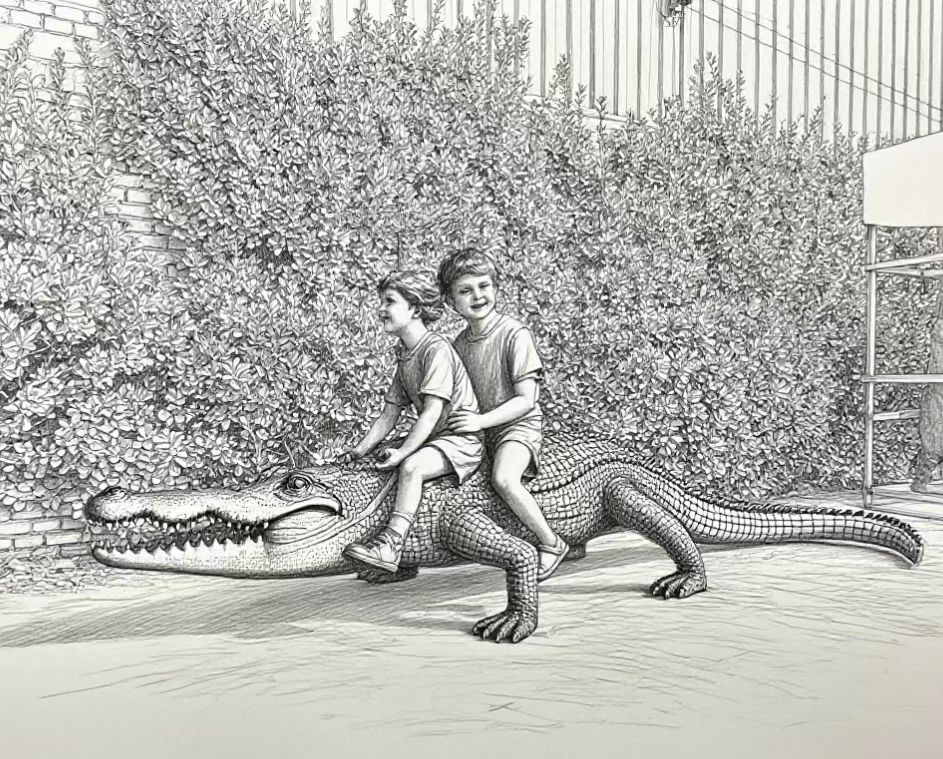

To explain how our artwork is made, we have documented the creation process for our monumental sculpture

Kids Riding in Crocodile Playing Sculpture (if you want to know more,click here)installed at the In a park

in Vietnam. To read more about the sculpture, its inspiration and story, read our Case Study.

Step 1: Inspiration for the Artwork

Every sculpture starts with an inspiration and design in our minds. For commissioned work, we will research

the sculpture’s history, meaning and purpose to bring the vision for the project alive. we create illustrated

renderings that depict the composition, scale and gestures of the art piece. For commissioned projects, we

will seek design approval at this stage with a rendering before moving forward in clay.

Step 2: Sculpting in Clay

We begin the creation process by working with models and reference to start the clay work.We will create a

“bone structure” or armature,At that point, we began the arduous phase of sculpting details in clay.

In preparation for the casting process, this piece was cut into multiple sections that were individually molded

and cast. The number of sections depends on the size and complexity of the piece. Each section was marked

with notches to ensure proper alignment when rejoined in metal.

Step 3: Making the Mold

To create a mold for the sculpture, we applied liquid silicon rubber to each section of the clay piece.

The rubber captured all of the sculpture’s details in a negative. When the silicon cured, we encased it

in a plaster mother mold to hold the form in place. The molds we create are “walnut shell” concepts,

so they are comprised of 2 halves separated by a seam. Molds are used to duplicate sculptures in a limited

edition and will be destroyed once the full edition has been cast. For one-of-a-kind pieces such as Kids Riding

in Crocodile Playing Sculpture , the mold was only used once, and then retired.

Step 4: Creating a Wax Pattern

After we removed the original clay sculpture from the rubber mold, we heated wax to approximately 200 degrees

Fahrenheit and poured it into the rubber mold, creating a thin coating. In creating wax patterns, the first “hot”

layer fills in the fine details while subsequent layers of cooler wax (160-180 degrees) build up the form to be 1/8 to

3/16 inch in thickness. After we pulled the cooled wax patterns from the mold, we hand finished, or “chased,” the

patterns to reveal our originally sculpted details and textures. Chasing means that we use sculpting tools and hot

tools to fix any bubbles or seam lines in the wax.

Step 5: Creating a Sand Shell Mold

Once we created the gated wax “tree,” We dipped the tree in a vat of slurry, coating both the inside and outside of the

hollow waxes. After dipping it in , we bathed it in silica sand. We repeated these steps 8-10 times, drying in between each

layer, to encase the waxes in a thick sand shell mold.

Step 6: Pouring the Bronze

Bronze is heated to high temperatures (around 950–1100°C) until it melts into a liquid. The molten bronze is carefully

poured into the mold.After cooling and solidifying,Break the sand shell to get the copper blank.

Step 9: Welding the Bronze

To reassemble the sculpture, we referred to photographs and measurements based on the original clay sculpture. We

welded the seams using a TIG welder, and a rod of the same bronze alloy. Like the wax patter, we chased and cleaned

the metal to remove any excess material and fill any pits. We sanded down the weld lines and used carabid-tipped

grinders to add surface texture to the piece, blending it with the rest of the sculpture. We take pride in the fact that

our seam lines cannot be detected, and we maintain the highest quality welds in strength and appearance.

Step 10: Applying the Patina

The process of applying coloration to bronze sculpture is called “patina.” We will use chemicals for thermal coloring

To protect the patina, we apply wax while the bronze is still hot. As it melts, the wax seals the metal’s pores and, once

cooled, several more layers are applied by hand and buffed to give the sculpture is final luster.

Contact: Mr.Li

Phone: 0086-15188960033

E-mail: sale2@tongyundiaosu.com

Whatsapp:008615188960033

Add: Changucheng Industrial Zone,Tang County,Baoding City,Hebei Province,China.

We chat